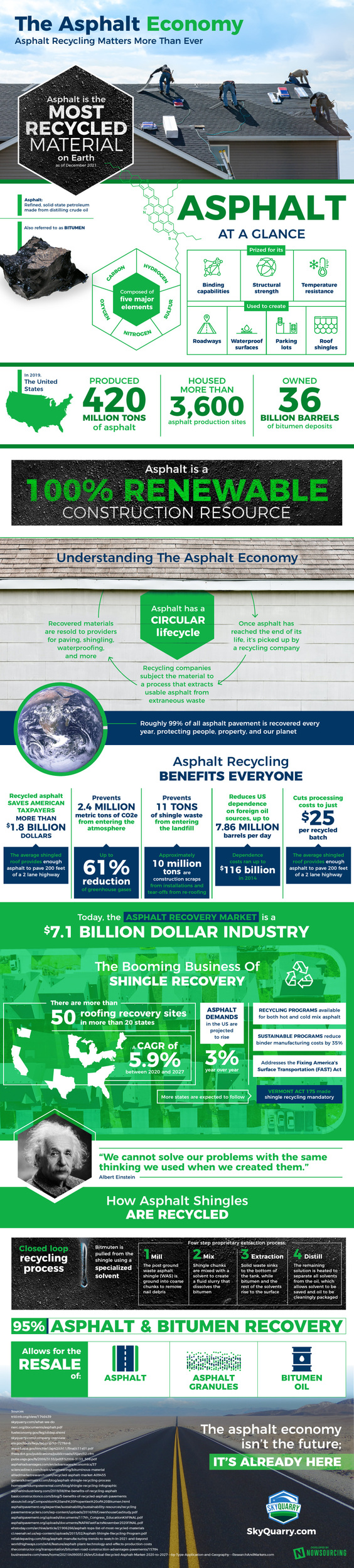

Asphalt (sometimes called bitumen) is a prized construction material. It has structural strength, powerful binding capabilities, and offers incredible resistance to extreme temperatures. This petroleum product is composed of 5 main elements that are mostly organic: hydrogen, carbon, nitrogen, oxygen, and sulfur. A mainstay in the construction world, bitumen is used to create parking lots, roads, and shingled roofs. While bitumen is occasionally found in nature, it is more common for asphalt to be manufactured from other forms of crude oil. The largest natural reserve of asphalt known to humanity is located in Alberta, Canada. This impressive reserve covers 140,000 square kilometers.

The Asphalt Economy

For those not blessed enough to find bitumen in its natural state, bitumen extraction from crude oil is a well established process. Vacuum distillation separates the compound from the other valuable components of crude oil, such as gasoline and diesel. The resulting material is typically further treated to extract small but worthwhile amounts of lubricants, which are put to use elsewhere. In a de-asphalting unit, the crude asphalt is treated with either propane or butane in a supercritical phase to extract molecules that are lighter, which are then separated. Further processing is possible by “blowing” the product, which generally means reacting it with oxygen. This step makes the product harder and more viscous.

Asphalt Recycling: Why it Matters

The US produces a dizzying amount of asphalt, to the tune of 420 million tons in the year 2019. At the same time, this country claimed 36 billion barrels of asphalt as its own. Unfortunately, asphalt produced new can have several negative impacts on the environment, such as damaging waste products and carbon emissions. One way to avoid these negative side effects is to recycle existing asphalt. Asphalt is a completely renewable construction resource. In recent years, an entire economy has grown up around the use and reuse of asphalt.

How does asphalt recycling work? The process is easy to follow. Whenever asphalt is discarded by its former users, it is handed off to a recycling company. Recycling companies then extract usable asphalt from any waste that collected on it during its lifespan. Consider roof shingles in the following example. In closed loop recycling, bitumen is pulled from the shingles with a specialized solvent. Next comes a proprietary extraction process with 4 steps.

The first step is milling, where asphalt shingles get ground up into coarse chunks to remove nail debris. Next comes mixing, in which chunks become mixed with solvent to create a fluid slurry capable of dissolving the bitumen. Third comes extraction: solid waste sinks to the bottom while bitumen and the solvents rise to the surface. Lastly, distillation happens. The remaining solution is heated to separate all solvents from the oil, which lets the solvent get reused in another cycle. The oil can also be cleanly packaged thanks to this step. Following that process, recovered materials get resold to providers for shingling, paving, waterproofing, or other tasks. Roughly 99% of all asphalt pavement is recovered every year, providing economical and environmental protection to all.

In Conclusion

The benefits of asphalt recycling stretch beyond environmental concerns. Reusing petroleum products reduces US dependence on foreign oil, a political issue that can run a tab of 7.86 million barrels daily. Sending shingle waste to a recycling company keeps up to 11 tons of shingle waste from clogging up a landfill, sparing city planners some of the pains of expanding waste collection sites. Approximately 10 million tons of shingle waste are construction scraps from installations or re-roofing. For perspective: a normal shingled roof from a house, where siding contractors are also important in home construction, provides enough asphalt to pave 200 feet of a highway.

Source: InvestSkyQuarry.com