Supply chain visibility (SCV) is the ability to track and monitor a product or shipment from its origin to its destination. This allows businesses to stay informed on their shipments’ progress, anticipate delays, and make adjustments if needed.

With eCommerce growth continuing at an exponential rate, supply chain visibility has become increasingly important for companies looking to remain competitive in today’s digital marketplace. Not only do businesses need to meet customer demands for fast delivery times, but they also need to manage costs, minimize losses, and ensure security.

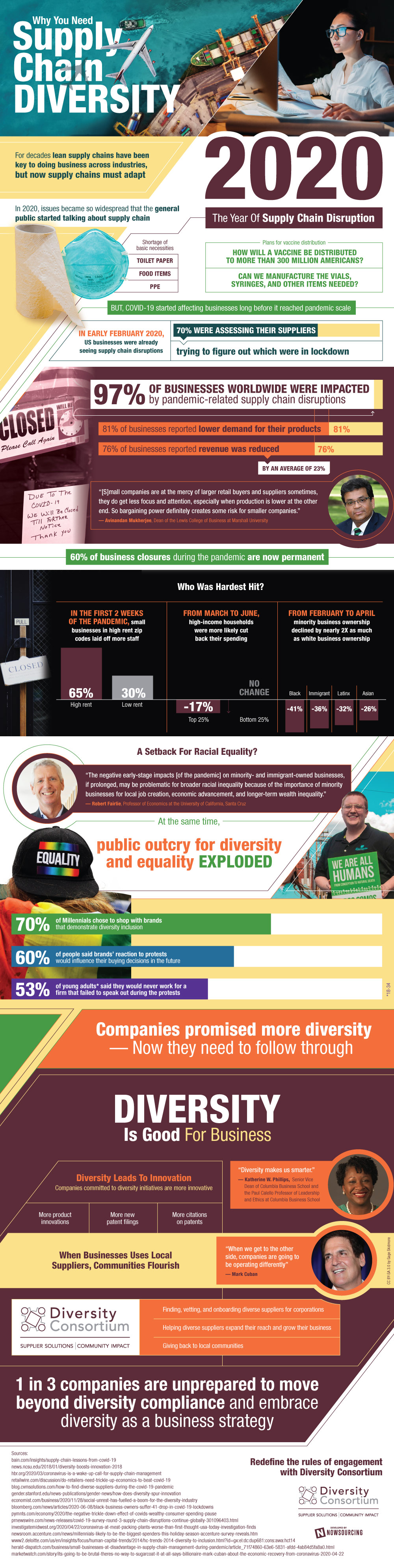

Be that as it may, only 65% of companies are able to report full visibility across their supply chains, and 43% of small businesses are not tracking inventory levels at all. With economic uncertainty on the horizon and customer expectations at an all-time high, now is the time to invest in supply chain visibility so you don’t find yourself falling behind while your competition sails away with their loyal customers.

Benefits of Supply Chain Visibility for Ecommerce Businesses

There are a multitude of benefits to be realized through the implementation of supply chain visibility in eCommerce. These include:

Improved customer satisfaction and loyalty

The more visibility you have into your own supply chain, the better equipped you are to anticipate customer needs and deliver products in a timely manner. With improved visibility, eCommerce businesses can increase customer satisfaction by reducing their response times, improving delivery accuracy, and providing customers with real-time updates about the status of their orders. This helps foster greater loyalty from customers, which in turn increases the likelihood of repeat business.

Reduced costs associated with inventory management

“Knowing inventory costs is extremely important because they affect the majority of decisions one makes as a retailer,” explains Abir Syed, co-founder of UpCounting, an eCommerce accounting firm.

Unsurprisingly, inventory management is the single largest expense for eCommerce businesses. For every dollar a US retailer generates through revenue, they have $1.35 tied up in inventory. As such, being able to accurately track and monitor inventory levels is essential for minimizing losses and maximizing efficiency.

By leveraging supply chain visibility technology, businesses can reduce the amount of inventory they need to keep in stock and their associated costs. This can be achieved through better forecasting and planning, more precise order fulfillment processes, and improved inventory accuracy.

Increased efficiency and speed of delivery

Knowing where products are throughout their journey allows businesses to better plan and adjust for delays, ensuring customers get their items as quickly as possible. Supply chain visibility also facilitates increased collaboration between all parties involved in the delivery process, allowing for a transparent and overall more efficient supply chain.

Enhanced flexibility and scalability in supply chains

As the demands of customers and markets shift, businesses need to be able to quickly adjust their supply chains accordingly. With supply chain visibility, businesses can quickly adapt to changing conditions, such as unexpected spikes in demand or supply disruptions. This increased flexibility and scalability of the supply chain is essential for businesses to remain competitive and responsive. This scalability also benefits businesses as they grow and expand into new markets.

Increased control over returns management

Returns are an unavoidable part of eCommerce and managing them can be difficult. Supply chain visibility gives businesses the ability to track a returned item as it moves through the supply chain and make adjustments to minimize losses. This includes tracking returned items on their journey back to the supplier, identifying potential issues and quickly resolving any discrepancies.

Challenges of Implementing Supply Chain Visibility

While the benefits of supply chain visibility are clear, there are still some challenges associated with its implementation. These include:

Establishing and maintaining relationships with suppliers

Before any supply chain visibility technology can be deployed, businesses need to build relationships with their suppliers. This requires open communication and collaboration between all parties involved, as well as a certain level of trust.

“When it comes to choosing partners, it’s wise to do some research to ensure the best deal possible while emphasizing transparency and flexibility. This is invaluable during times of frequent supply chain disruption,” explains Roei Yellin, Co-Founder & Chief Revenue Officer of 8fig, a planning and funding platform for eCommerce companies.

“Sellers shouldn’t be afraid to negotiate for a better deal and they should make sure that communication is open and honest. This is true of suppliers, 3PLs (third-party logistics providers) and any other partners brought in to help manage the supply chain,” concludes Yellin.

Complexity of the supply chain and data formats

Securing buy-in from all parties and managing the data exchange between different organizations is challenging. Not only do various supply chain participants have differing needs and processes, they also use different systems. Unifying these systems and ensuring harmonious data exchange can be difficult.

To overcome this, businesses need to create a single source of truth that all supply chain participants can work from. This means creating common protocols and standards that all parties are comfortable with and can adhere to, and potentially leveraging a third-party solution to manage the data exchange.

Costs associated with technology and infrastructure

The technology and infrastructure required for supply chain visibility can be costly. Businesses need to invest in the right hardware, software, and people to ensure that the system is secure and effective.

Fortunately, there are solutions to this issue. RFID and code-based tracking solutions, in particular, are relatively inexpensive and easy to implement. Companies such as Scurri allow you to easily create a single bar code for all carriers, as well as a reporting dashboard that gives you full control over your operations with actionable insights.

Cybersecurity concerns

Data is the lifeblood of supply chain visibility and ensuring its security is paramount. However, supply chains are coming under increasing attack from hackers and malicious actors, making them vulnerable to data theft and manipulation.

In fact, 97% of organizations say they have experienced the negative consequences of a supply chain cyber breach within their operations, demonstrating just how prevalent these attacks have become.

As such, businesses need to ensure that they have the appropriate protocols in place to protect their data from cyber-attacks. This includes using secure networks and encryption, as well as regularly auditing system access and usage. Multichannel cyber security solutions, such as VMware, can also be of great help in mitigating cyber risks.

Conclusion

Supply chain visibility is becoming increasingly important in today’s volatile and highly competitive marketplace. However, if businesses are to reap the full benefits of a visible supply chain, they must first overcome the various challenges associated with implementation.

Ultimately, with careful planning, a comprehensive approach to risk management, and the right technology in place, businesses can ensure that their supply chain visibility efforts are successful and that they remain agile and competitive in the long run.