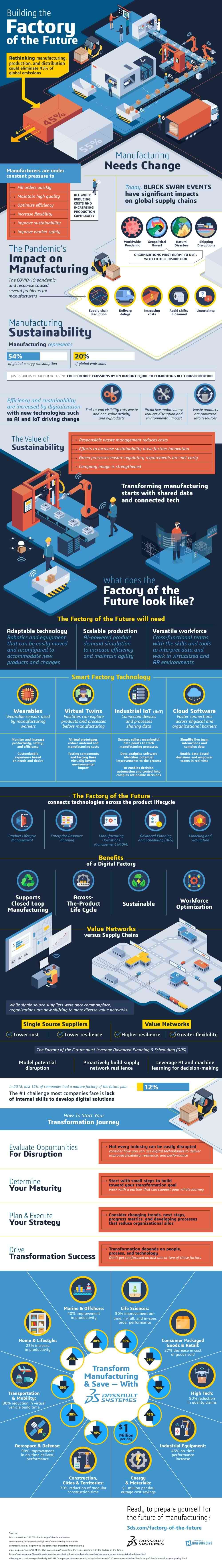

The COVID pandemic, despite its disruptive effects on every aspect of our lives (not to mention all the painful losses we’ve endured since 2020), has caused us to re-examine and rethink how we function in almost every area. From personal interactions, to how we work, how we conduct healthcare procedures, to how we eat and how much we cook, and everything in between; COVID has induced a multitude of changes, and many of them have been for the better. Let’s learn more about building the factory of the future below.

One industry that has been greatly affected by COVID is that of manufacturing. Manufacturers saw many issues arise due to the pandemic. They saw supply chain disruptions, delivery delays, increased costs, rapid changes in demand, and general uncertainty. All of these issues only served to highlight the fact that manufacturing already needed a facelift.

Manufacturing Needs an Update

A pandemic is certainly not the only unexpected event that could affect manufacturing. Other concerns are things like geopolitical unrest, natural disasters, and shipping disruptions. These, and other potential problems, mean that manufacturers must be prepared and have plans in place to keep moving forward, despite these harmful events.

Of course, the potential for the unexpected is certainly not the only reason why manufacturing needs to be updated. The manufacturing process itself is in great need of change as manufacturing, production, and distribution is currently responsible for a large portion of the world’s pollution. In fact, altering these processes to “greener” methods could eliminate 45% of global emissions.

Not only would updates to manufacturing processes be good for the environment, they would also be beneficial to manufacturers who are feeling the strain of trying to fill orders quickly, maintain product quality, work efficiently, increase flexibility, maintain safety, and improve sustainability, even as they reduce costs and increase production complexity. These manufacturers are under massive pressures which create other sustainability issues from within.

Manufacturing With Sustainability in Mind

Bringing manufacturing up to speed with modern digitalization would increase both sustainability and efficiency. Not only that, but currently manufacturing represents 54% of the world’s energy consumption and 20% of global emissions. Rethinking just 5 areas of manufacturing could reduce emissions by an amount equal to eliminating all forms of modern transportation. With new AI and IoT technologies, these changes are 100% possible.

Sustainability in manufacturing is beneficial to all and could be invaluable. For instance, responsible waste management would reduce costs. New ideas behind sustainability drive innovation; green processes ensure early completion of regulatory requirements; and the company image is strengthened by its embrace of environmentally friendly processes.

The first step to achieving all of this is through shared data and connected tech. Manufacturing factories of the future must include adaptable technology, scalable production, and a versatile workforce. It also must include smart technologies such as wearable sensors for manufacturing workers, virtual twins to explore products and processes prior to manufacturing, industrial IoT, and cloud software for faster connections across physician and organizational barriers.

Through updating manufacturing processes and procedures, manufacturers can not only make a significant positive impact on the environment, but they can also plan for the future and be prepared for the unexpected without missing a beat.

Learn more about building the factory of the future in the infographic below: